“VR” Repairs & T/O Certifications

Extreme Force Valve has the authority to use the VR Stamp. Our accepted quality system meets the standards established by the National Board. Our VR Stamp signifies that our quality system complies with the boards requirements for proper repair of ASME code section I and VIII valves that have been NB capacity tested

Extreme VR certification allows for special processes for conversion, machining of parts, and welding (by “R” stamp holder).

The T/O mark signifies that our valves meet all the requirements for in service testing and certifications of pressure relief valves, providing they pass all testing required and no repairs are needed. Only minor set pressure adjustments are allowed. There is no need to disassemble a valve that operates properly.

Servicing ALL types, brands, and sizes of Safety/Relief valves.

Servicing Most Types, Brands and Sizes of Industrial Valves

The team at Extreme Force Valve will do your job to the highest standards, on time, every time.

Our customers appreciate our quick turnaround, quality service, and fair pricing. Utilizing an extensive network of resources we provide any additional necessary services above and beyond our in-house capabilities. We are your one stop shop for all of your Safety/Relief valve needs.

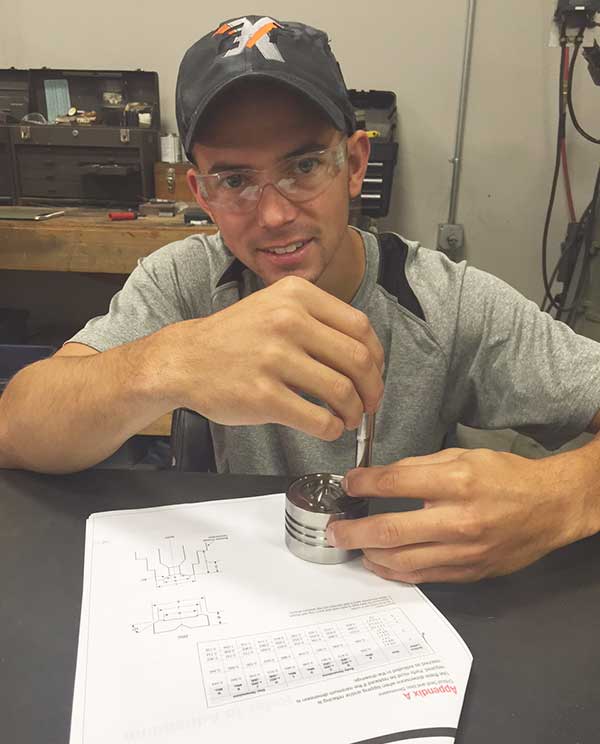

Let us save you money. Before you purchase replacement valves CALL US. Our Special Process Certification allows us to re-work slightly damaged parts when possible to stay within OEM specifications. This allows significant cost savings compared to purchasing new valves.

- Up to 4000 psi set pressures on Section VIII Air/Gas and Liquid valves

- Up to 540 psi set pressure on Section I and Section VIII Steam valves

Have Special Process Certificate to perform machining on PRV parts. This allows up to rework parts when possible to stay within OEM specifications. This saves our customers money by not having to purchase replacement load train parts when they are slightly damaged.

- Industrial repair and full machine shop services for non-safety valve work

- Certified Pressure testing capabilities to meet customer requirements for all types of valves and vessels

- Valve Conversions & Set Pressure Changes

Give us a call today and let’s discuss your needs. 618.471.9016

- Quick turnaround

- Competitive pricing

- Extensive network of resources allows us to provide you with any necessary services above and beyond our in-house capabilities

- Extreme utilizes trusted parts suppliers throughout the country to ensure best pricing and delivery of required parts. OEM COC paperwork is kept on all parts for traceability

- Documentation – Ability to produce computerized test reports to provide documentation of valve performance when tested – These reports are available on all Safety/Relief Valves at no cost

- We welcome walk-in machining and welding projects brought in by private individuals

All valves undergo thorough testing and analysis with our state of the art testing equipment. You can rest assured that your completed product will hold up to your needs.