Committed to Quality

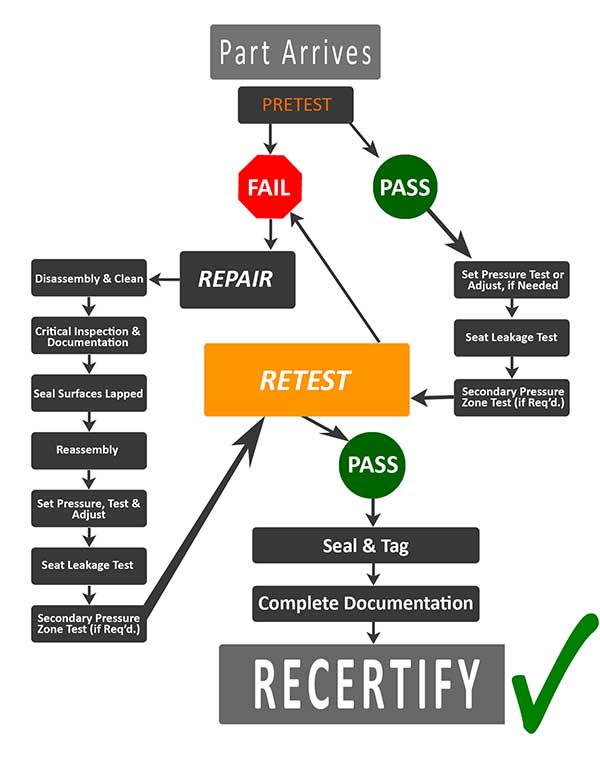

When valves arrive at our facility, valves are pretested and visually inspected so the performance of each valve can be recorded. This is important so that customers can be notified if valves removed from service are in working order or not. Valves that pass all pretesting, can typically be put through all testing requirements of the Test Only program laid out by the National Board of Boiler and Pressure Vessel Inspectors, certified by T/O without any repair.

Valve Repair

Valves that fail pretesting must be repaired and then pass testing in order to be certified. All Valve repairs, when eligible, are performed to the standards of the National Board “VR” Program. To ensure consistent quality repairs, the National Board has audited our processes and accepted our Quality Control Manual. To be eligible for a stamped VR repair, a valve must both bear the NB stamp as well as either an ASME UV or V stamp on the nameplate.

Having the NB stamp and ASME designator stamp on a valve ensures that the valve has been designed and originally built to ASME Code Section I or Section VIII requirements and have been approved by the NB thru certified capacity testing.

Valve Inspection

Valves to be repaired must be fully disassembled, cleaned and inspected. When the critical inspection is performed on the valve parts, “as found” dimensions are documented. Once documented, dimensions are evaluated against OEM specifications to determine if existing parts are still within working tolerances. Any parts suspected of non-conformance must either be machined back to OEM tolerance if possible, or must be replaced with new parts traceable back to the OEM.

All steps of repair are documented. Standard Practice ensures that all seat surfaces are lapped prior to reassembly. Once assembled, valves are tested for proper pressure settings and adjusted as needed, tested for seat leakage issues, and then perform a secondary Pressure zone test (if required) to ensure that valves with closed bonnets are air tight.

Our Valve Recertification Process

Valve Testing

Testing is performed on modern test systems with Graphs and Electronic Travelers containing all details of repairs and testing. Valves must perform like new after repair in order to be certified.

Copies of test reports are given to the customer for their records and kept on file with Extreme. “When valves are sent in repetitively for evaluation, historical information is available to help diagnose etc.